Design and Fabrication

Design and Fabrication

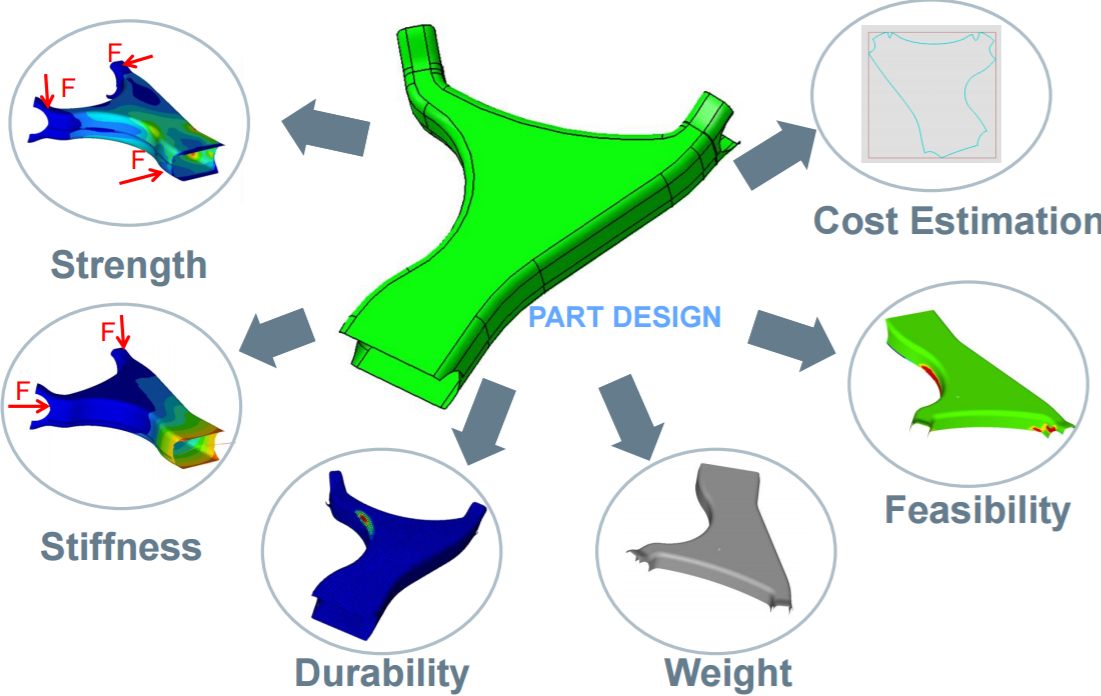

AeroChamp has established itself as a leading design centre for aircraft components and sub-assemblies. Our capability includes 3D scanning of components, engineering drawings, 3D modeling, validation and manufacturing. Our team consists of experienced mechanical and electronic engineers who understand the airworthiness requirements of every component. Our project management team understands the regulatory compliance requirements for certification of such parts manufactured by us.

Our design centre is equipped with CAD/CAM, CREO, Solid works, Catia and other software tools to handle any complex designning and validation job. We offer 3D Scanning, 3D Modelling and 3D Printing Services to the aviation industry.

Our mechanical component manufacturing capability includes milling and machining using sophisticated 3 axis lathe machine, 5 axis CNC machine, laser cutting machine, water jet cutting machine and additive 3D printing technology.

Our electronics design and manufacturing department is engaged in development of aircraft LED lights, USB passenger seat power supply and various other non-critical components. We aim to enhance our capability to design and manufacture cockpit avionics equipment in the near future as a tier 2 supplier to the leading OEMs under their quality system.

We are currently supporting leading airlines in Asia for their cabin, galley and lav parts repair and replication, thus reducing their maintenance cost. As an extended DOA and working closely with a network of FAA DERs, we are able to offer engineering document pack and COC for parts manufactured by us. We can meet Part 21 (G) & (J) compliance as per the requirements of the customers.

Based on our design and manufacturing capability, we have supported many business jet and helicopter operators with metal and composite parts reverse engineering with performance improvement. We have fabricated many obsolete or hard-to-find parts through our reverse engineering capability, which involves very high precision tools and machineries to achieve upto 5 microns accuracy.