Aircraft Component Reverse Engineering

Reverse Engineering of Defence Aircraft Parts

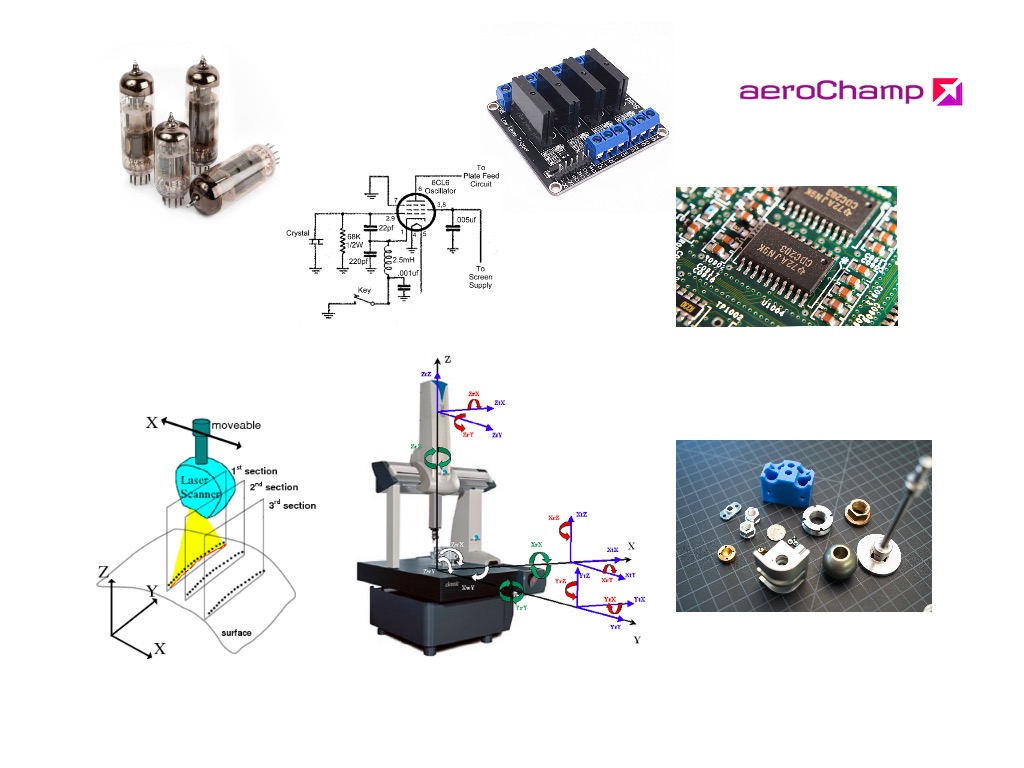

Reverse engineering is the process of evaluating an existing part to re-design and manufacture it for life and performance enhancement. AeroChamp has evolved as a leading reverse engineering company for both mechanical and electronics sub-assemblies. On the basis of the experience of our design engineers, we carryout evaluation of the part through probe and laser CMM (coordinate measuring machine) and various other tools, after which we develop the design using 2D drawing and 3D modelling software tools like Autocad, Catia, Solid Works and CREO. Once the design is developed, it undergoes rigorous performance analysis using software simulators.

After successful analysis of the design and overcoming the errors if any, we manufacture prototype of the part under development. This prototype is then tested on various test jigs before subjecting it to live performance test. On successful live test, the design is once again reviewed for commercial production.

We start the commercial production of such reverse-engineering parts after receiving the performance approval from the customer. VMC, Multi-axis CNC, Wire cutting, laser cutting, water jet cutting, milling, hardening, electroplating and various other processes are carried out to manufacture mechanical parts with a precision upto 5 microns. We extensively use additive 3D printing technology to produce small quantities of non-critical air-borne parts.

Stencil, pick & place, wave soldering and other types of processes are applied for commercial production of electronic circuits. We have a logic development and digital circuit design team, which can covert most analogue circuits into digital design. We expertise in conversion of old vavle, pentode and relay type circuits into solid state circuit with improved reliability and performance. Our team has carried out many such conversions for airborne sub-assemblies.